| Title | Pages |

|---|---|

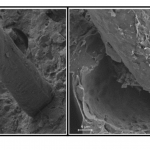

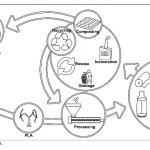

| Comparison of Wood Fiber Reinforced PLA Matrix Bio-Composites Produced By Injection Molding and Fused Filament Fabrication (Fff) Methods The Fused Filament Fabrication (FFF) method is the most popular method preferred for shaping polymers with AM. FFF is known to have low cost and high printing speeds compared to other AM techniques. PLA material, which is a completely bio-based thermoplastic polymer with many desirable properties, including easy processing ability, strength, hardness, and biodegradability, is widely used in material processing by the FFF method. In this study, the PLA matrix was reinforced with natural fibers to increase the mechanical properties and contribute to recycling. Bio-composite compounds with 15 wt.% wood fiber reinforced PLA matrix was prepared using a twin-screw extruder. Test specimens were produced the FFF method and injection molding method. Thermal analysis of the prepared compounds, filaments, and produced specimens was carried out. A decrease in the Tg value of the compound reinforced with natural fiber was observed, while an increase in the Tm value was observed. The Tg value of the specimens produced by the FFF method increased compared to the injection specimens. It was determined that the stress at break values of the specimens produced by injection were 2 times higher than the specimens produced by FFF. The impact strength of the specimens produced with injection molding is 51.75% higher than the specimens produced with FFF. The bio-composite materials produced in the study were examined under scanning electron microscopy (SEM). Surface interactions and homogeneous fiber distribution between matrix and fiber were investigated.

|

215 - 226 |

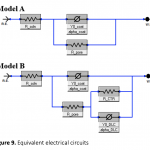

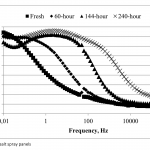

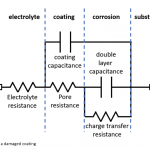

| Comparison of Accelerated Exposure Tests on Organic Coatings via Electrochemical Means Organic coatings are widely employed on the protection of metallic surfaces from the effects of the corrosion. While the mechanisms of corrosion protection by organic coatings are well known, observing these mechanism’s development is not possible with traditional accelerated exposure tests like salt spray (ASTM B-117) and condensation chamber (ASTM D-4585) tests. In these tests, corrosion can only be observed and evaluated after its visual clues emerge, which can be much later than the start of the actual corrosion under the coating, requiring long test durations to differentiate between samples. In this study, progress of degradation on an organic coating during two different accelerated exposure tests was investigated. Measuring electrical impedance spectra (EIS) of fresh and different levels of exposed coatings and modelling them in an appropriate equivalent electrical circuit showed the level of degradation underneath the coating. Although visual inspection did not reveal any corrosion, with EIS, corrosion was observed in just 60 hours of salt spray test exposure while 240 hours of condensation chamber test was not enough to initiate corrosion. Results showed that for the coating system tested, salt spray imparts much higher levels of degradation compared to the condensation chamber test.

|

227 - 237 |

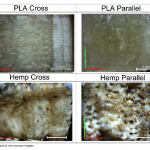

| Hemp Reinforced Polylactic Acid (PLA) Composite Produced By Fused Filament Fabrication (FFF) Reinforcement of polymer matrix with natural fiber can provide an increase in mechanical properties of the related com- posite. Since thermoplastics, especially biocomposite materials are recyclable, they contribute to a sustainable ecosystem. In this study, 10% by weight hemp reinforced polylactic acid (PLA) matrix compounds were produced. Tensile test specimens were performed in two different infill patterns, parallel and +/- 45° cross, using the Fused Filament Fabrication (FFF) method from the developed biocomposite filaments. Ultimate tensile stress increases approximately 20%. It has been observed that the geometry of the infill pattern greatly affects the tensile strength. In addition, through optical and scanning electron microscopy (SEM) the produced composite filaments were examined. Surface interactions and homogeneous fiber distribution between PLA and hemp were investigated. As a result, hemp was used as a reinforcement material in the study. Homogeneous distribution is very important in the preparation of the compounds and a twin-screw extruder was used to achieve this. However, it has been observed that the interface between fiber and matrix is insufficient. This situation negatively affects structural performance. On the other hand, the addition of hemp decreases the thermal resistance and melting temperature and increases the glass transition temperature compared to pure PLA.

|

239 - 246 |

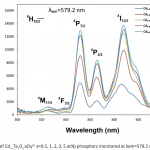

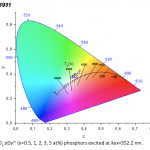

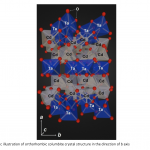

| Assessing of Photoluminescence and Structural Properties of Dy+3 doped Cadmium Tantalate Phosphor on the Basis of Charge Balance Based on the charge balance, trivalent dysprosium doped Cd1-xTa2O6:xDy3+ (x=0.5, 1, 2, 3, 5 at%) phosphor series was fabricated by solid state reaction route at 1100 °C for 8 h. The synthesized phosphors were investigated by XRD (X-ray diffraction), SEM (scanning electron microscopy), and PL (photoluminescence) analyses. XRD and SEM analyzes revealed the orthorhombic colombite crystal structure and the presence of oval-like and shapeless morphology with submicron and several micron grain sizes, respectively. With the excitation of 387.8 nm, the phosphors exhibited blue and yellow emissions at 482.4 nm and 578.5 nm depending on the 4F9/2→6H15/2 and 4F9/2→6H13/2 transitions of Dy3+, respectively. The emission intensity of cadmium tantalate phosphor increased with increasing Dy3+ concentration up to x=5 at% value, and did not occurred the concentration quenching which reduces emission intensity. The reason why concentration quenching did not occur can be attributed to the reduction of structural defects due to the improvement in charge balance and the reduction of the conversion of excitation energy to nonradiative transitions. The Commission Internationale d’Eclairage (CIE) coordinates of Cd1-xTa2O6:xDy3+ (x=0.5, 1, 2, 3, 5 at%) phosphors were found near the white region in the chromaticity diagram.

|

247 - 254 |

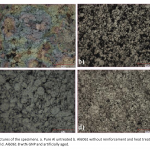

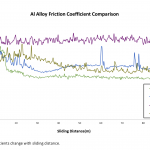

| The Effect of Aging Process on Wear Properties of Al6061/GNP Metal Matrix Composite In this study, the effect of aging on wear characteristics of the nano GNP reinforced Al6061 metal matrix was investigated. In this scope, the samples were produced by hot press at 500°C temperature under 50MP a pressure for 30 minutes.The wear characteristics of the composites were determined using the ball-on disc wear test method. The effect of aging on the friction coefficient and wear ratio was investigated. Graphene reinforcement significantly increased the friction coefficient between the stainless-steel ball and specimen but the aging process lowered the coefficient of friction to a better level. Also, artificially aged specimens showed significant increase in hardness values. Key factors affecting the mechanical performance of the Al based alloy is reinforcement and aging process.

|

255 - 261 |

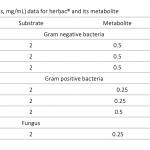

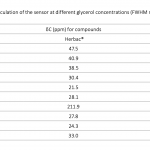

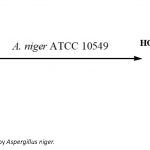

| Microbial Transformation of 3,3-Dimethylcyclohexyl methyl ketone and Antimicrobial Evaluation 3,3-Dimethylcyclohexyl methyl ketone (Herbac®) is a fine fragrance compound used in the cosmetic industry. In this study, the biological derivatisation of the substrate 3,3-dimethylcyclohexyl methyl ketone by 18 fungal cultures was carried out to obtain new derivatives. Among the evaluated, the plant fungus Aspergillus niger ATCC 10549, biotransformed the substrate to the 4-hydroxy derivative in 19% yield. The structure was determined by using NMR and GC-MS methods. In addition, the antimicrobial activity of Herbac® with the metabolite against a panel of pathogenic microbial strains were evaluated using an in vitro microdilution assay. The results showed that the metabolite was relatively more susceptible to the pathogens compared to the substrate

|

263 - 267 |

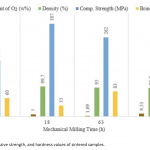

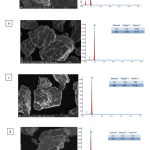

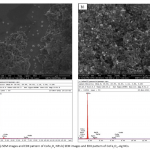

| Effect Of Ball Milling Time on Microstructural Properties of Mg/MgO Magnesium and its alloys are desired for mechanical properties and biocompatibility in many research fields. The generation speed of MgO as oxide layers is very rapid, sometimes even ending with inflammation. This study focused on mechanical milling of Mg for different hours of time and its effects on mechanical properties as in density, compressive strength, and hardness values. The effect of milling times on Mg/MgO powder composite formation was investigated. Scanning electron microscope (SEM) images and X-ray spectroscopy (EDS) results were analyzed.

|

269 - 274 |

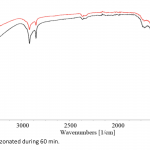

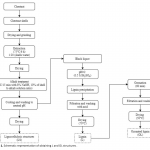

| Alkali Lignin and Alkali Combined Ozone-Treated Lignin for Sustainable Food Packaging Applications This study aimed to utilize the lignin-based structures extracted from chestnut shells, an agricultural waste, in chitosan (CH) films. Lignin (L) was isolated from chestnut shells by alkali treatment (8% NaOH, 120°C/15 min), then sulfuric acid precipitation (0.5M) and drying. In addition, black liquor was treated with ozone to obtain more homogeneous and compatible lignin fractions. Black liquor obtained after an alkali treatment was further treated with ozone at ambient conditions to gain alkali combined ozone-treated lignin (OL). L and OL were added to CH film-forming solutions to fabricate CH-L and CH-OL films and films were characterized by barrier against water (WVP), morphological, thermal properties, optical and antioxidant properties. Fourier transform infrared (FTIR) data confirmed that the isolated L and OL had different structures, and the films indicated a potential interaction between lignin-based structures and CH matrices. Moreover, incorporating L and OL into the CH films increased the opacity and antioxidant activity of films. The addition of lignin-based structures caused a plasticizing effect on the CH films, corresponding with the tensile and thermal properties. The WVP of CH was not significantly influenced upon the addition of lignin-based structures (p>0.05) .

|

275 - 285 |

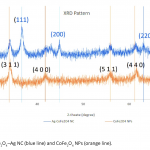

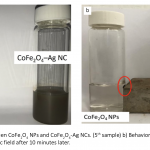

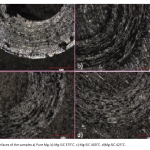

| Preparation Cobalt Ferrite–Silver Nanocomposite Via Green Chemistry Approach Nanocomposites are formed by joining two or more materials, at least one of which must have a size in the nanometer range (1 nm -100 nm). In this study, cobalt ferrite-silver nanocomposite was prepared with a green synthesis approach. The aim was to combine the magnetic properties of cobalt-ferrite nanoparticles with both the antimicrobial and conductivity properties of silver nanoparticles. Thus, the prepared material can be used for biological, optical, electrical, and magnetic applications. Cobalt ferrite nanoparticles were prepared using the co-precipitation method. Silver nanostructures were incorporated into cobalt ferrite nanoparticles using waste grass extract. Scanning Electron Microscope (SEM), Infrared Spectrometer, UV-VIS Spectrometer, X-ray Diffraction (XRD) Spectrometer, Dynamic Light Scattering (DLS) Technique were used for characterization studies.

|

287 - 293 |

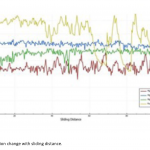

| Investigation of Dry Sliding Wear Behavior of Mg-SiC Alloys Produced by Powder Metallurgy Method In recent years, Mg alloys have great promise for weight-saving applications, because of their superior properties over monolithic metals, in the field of automotive and aerospace industries. In this study, the dry sliding wear behavior of Mg- SiC alloys with different sintering temperatures (375°C, 400°C, 425°C) were investigated. Mg with %10 weight SiC powders were mechanically mixed and alloyed and then fabricated successfully via fast heating under vacuumed argon atmosphere. The friction coefficient, hardness value, and wear resistance of the alloys were higher than those of the pure Mg. The increase in the sintering temperature of the Mg-SiC alloys up to 425°C caused an increase in the friction coefficient and a decrease in the wear mass loss respectively.

|

295 - 299 |

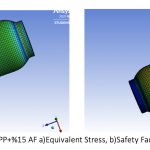

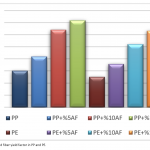

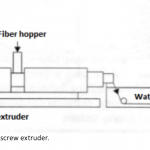

| High Pressure Resistant Aramid Fiber Reinforced Polymer Matrix Composite Pipe Design In this study, a total of 6 different composites were obtained by adding 5%, 10% and 15% chopped aramid fiber reinforcement in 6 mm dimensions to each of the polypropylene and polyethylene matrix elements under the same production method and same conditions. The reinforcement and matrix materials were mixed using the extrusion method and then formed into plates by the press molding technique. The mechanical properties of these composites were investigated by performing tensile and charpy tests, and the effects of the surface energy of the matrix on the composite were discussed. S/N ratios were calculated for the mechanical properties of the composites and the effect of the matrix, fiber and additive ratios on mechanical properties was determined using analysis of variance (ANOVA). According to the Signal/Noise (S/N) ratios and ANOVA results, it was observed that the composites had different effects on the mechanical properties. Pipes are designed considering the mechanical properties of composite materials with 15% aramid fiber added to each matrix element. The composite pipe design to be pressure tested was designed in Solidworks program with a length of 500 mm according to ISO 1167 standards. Pipe dimensions with an outer diameter of 125mm, which are used as a standard in natural gas infrastructure works, are taken as reference.

|

301 - 312 |

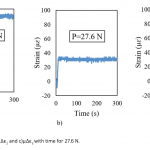

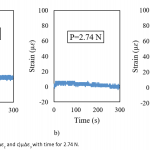

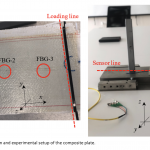

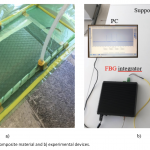

| Structural Health Monitoring by Using Fiber Optic Sensors in Composite Materials In this study, design and application of a structural health monitoring (SHM) in composite materials with fiber bragg grating (FBG) sensors are investigated. The designed structure consists of laminated composite material that was produced by vacuum infusion method. The composite specimen was obtained by embedding a FBG sensor between the 12-layer glass layers. Moreover, SHM of the produced composite material was achieved by obtaining the strain data from the sensor embedded in the composite material. Application was carried out by making the composite plate fixed support on one side and applying different loads to the specimen. Strain ratios of these loads are obtained and the results graphics are shown.

|

313 - 318 |